-

3D measurement

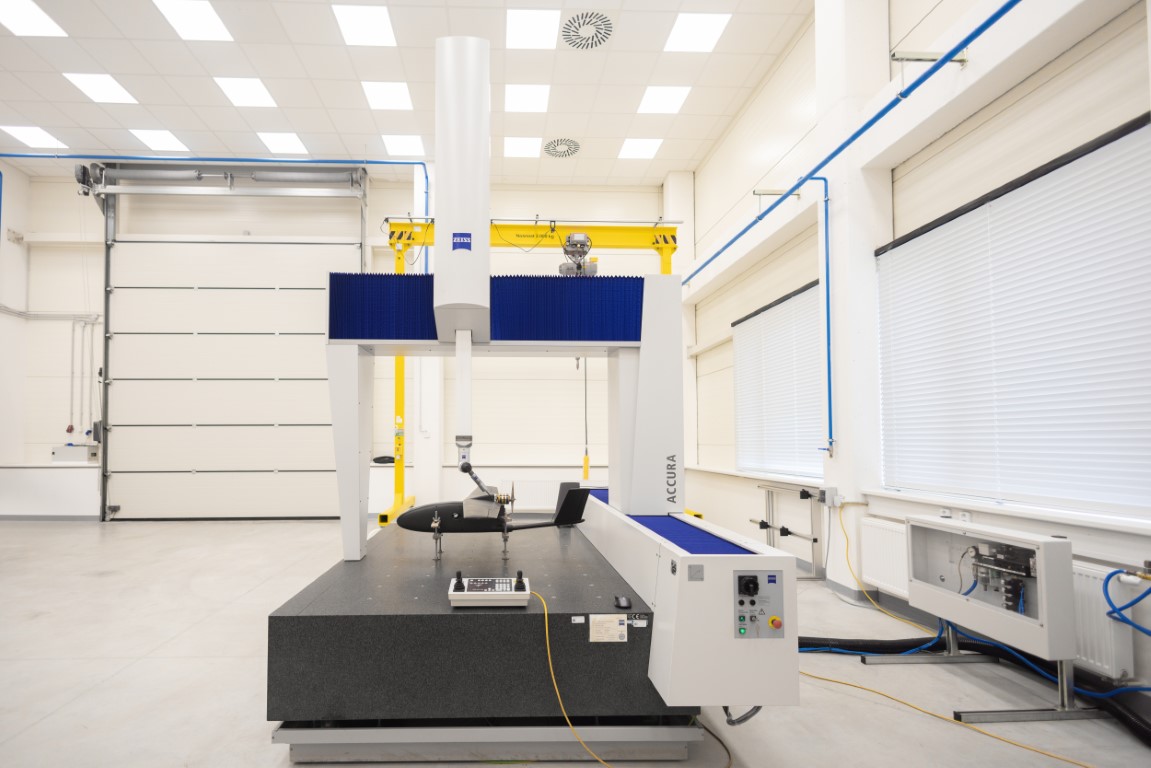

The Zeiss coordinate measuring machine enables the geometric measurements of parts to be determined in both manual and automatic (CNC) scanning modes.

3D measurement

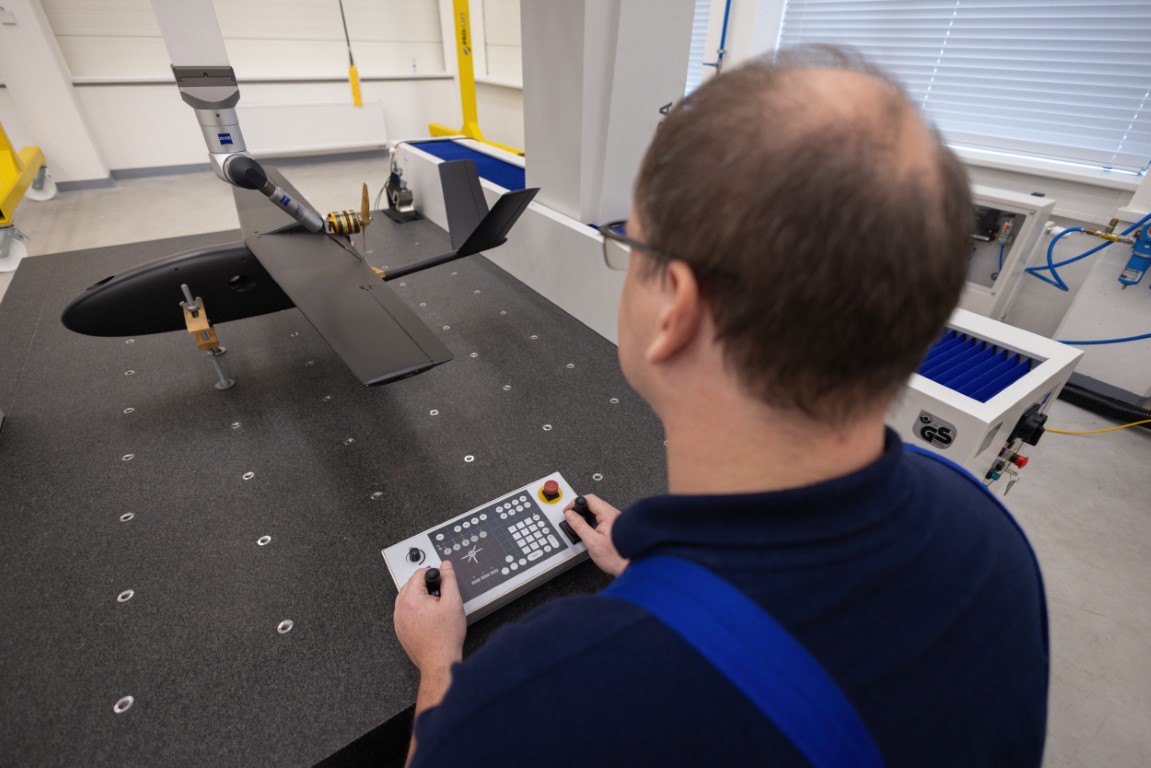

The Zeiss coordinate measuring machine, including the operating software (Calypso), enables the geometric measurements of parts to be determined in both manual and automatic (CNC) scanning modes. It measures shape deviations and positions of individual elements, including general surfaces.

The measurement is based on a touch probe with the possibility of single-point coordinates determination or scanning, where the probe travels along a defined path and scans continuously.

Measured points can be exported and further processed, e.g. for the creation of CAD models (digitization).

SERVICE OFFER:

- Measurement of mass-produced products, prototypes, models, and fixtures up to 1.8 m in length according to drawings or CAD models

- Evaluation of results

- Digitization of simple parts (creation of CAD model)

- Affordable prices and flexible approach

EQUIPMENT:

- Carl Zeiss ACCURA 10 bridge coordinate measuring machine with a range of 1000 × 1200 × 1800 mm

- Calypso operating software

- Volumetric and surface modeling in common CAD formats (Rhinoceros software)